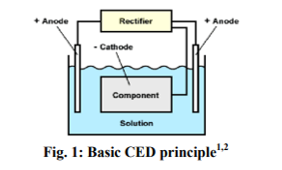

Cathodic Electro Deposition (CED) is a process of coating an object having a conductive surface connected to a circuit as the cathode, by positively charged paint particles suspended in aqueous medium, under direct current1,2. CED coating is most widely used for automobile Components.

Our Process

CED is most advanced and environment friendly water based coating to be done on metal components. A combination of dip and spray ensures reach of paint at every corner of component having intrinsic shape as well. CED is chemically resistant, mechanically durable, and pleasant in appearance having very good salt spray life and is sought for by all automobile users2 . ED Coating is the first coating layer which gives the corrosion resistant and good adhesion property for the next coating layer. The ED coating will be maintained min of 20 micron thickness. ED process is done in the car bodies by having the facility to hold the product in a carrier/Hangar, with proper seating & locking arrangements. Here the study aims, to reduce the running cost of the process by reducing the energy consumption by implementing the small modification in the car body holding carrier/hangar.

Why do we use it

- The process of CED coating provides the ability to coat complex parts or surfaces that are hard to reach, like thin edges or corners of equipment. Manual labour is not needed to apply paint; the CED Coating system becomes easy, fast in operation and highly productive coating process.

- corrosion protection right into every corner.

- Very uniform coat thickness structure.

- Very good adhesion behaviour.

- Coating of hollow parts and workpieces with complicated geometries possible.

- Top coat painting with acrylic paints.

- Economical coating of large and small parts.

- SST Life Obtained 720 to 1000hrs According to ASTM B:117

Get Expert Advice

Get Expert Advice  enquiries Now

enquiries Now quality Certificate

quality Certificate Achievement

Achievement