In Zinc Nickle Plating tank During application of current Oxygen generate which causes cyanide in tank which is harmful for zinc

nickel bath, hence Membrane Anode provided with flow meter in zinc nickel tank to prevent occurrence of cyanide.

During application of current Oxygen generate which causes cyanide in tank which is harmful for zinc nickel bath

MEMBRANE ANODES INSTALLED IN ZINC NICKEL PLATING TANK

Flow meter provided in zinc tank

Click Here To Download the Brochure

Zinc-Nickel is a high performance coating that offers exceptional corrosion resistance particularly for parts used in harsh environments. Alloying Nickel with Zinc creates a unique composition that will corrode slower than zinc alone. With a makeup of approximately 12-15% nickel and the remainder zinc, this alloy coating can provide up to ten times the protection of conventional zinc plating.

Our Process

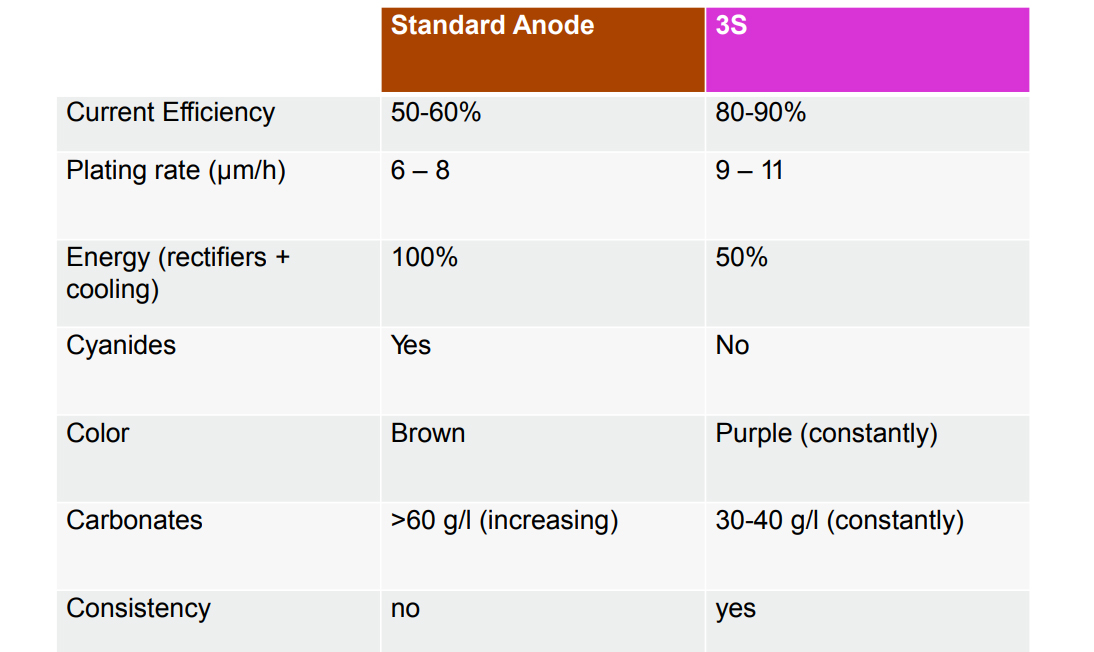

Comparison of Standard

Anode and 3S

There is an increasing demand across industries for the high-corrosion resistance of Zinc-Nickel due to factors such as extended product warranties, longer life cycle requirements, more stringent safety standards and reduction of environmental impact. Zinc-Nickel is routinely specified for the following applications

- Agricultural Machinery

- Heavy Equipment

- Oil + Gas

- Automotive

- Hydraulics

- Electrical Transmission

It is also a suitable alternative to Cadmium Plating, a common finish utilized in highly-corrosive environments. Cadmium plating has been phased out due to its environmental concerns, and for many companies has been effectively replaced by Zinc Nickel

Why do we use it?

It is a long established fact that a reader will be distracted by the readable content of a page when looking at its layout. The point of using Lorem Ipsum is that it has a more-or-less normal distribution of letters, as opposed to using ‘Content here, content here’, making it look like readable English. Many desktop publishing packages and web page editors now use Lorem Ipsum as their default model text, and a search for ‘lorem ipsum’ will uncover many web sites still in their infancy. Various versions have evolved over the years, sometimes by accident, sometimes on purpose (injected humour and the like).

- Excellent Corrosion Protection – Up to 10 times more protection than conventional zinc.

- Ideal for outdoor use or parts subject to harsh environments.

- Ductile coating that maintains good adhesion after post-plate forming or bending.

- Limits thermal stress to parts subjected to high temperatures.

- Heat resistant and can maintain good corrosion protection after being exposed to high temperatures.

- Can be a great alternative to cadmium plating or hot dip galvanizing in certain applications.

- Provides a thin, smooth, uniform coating that can be used on threaded parts or components with tight dimensional tolerances.

- Excellent corrosion protection when used as an undercoat treatment before paint or powder coat finishes

SST life obtained 2000+ hours in silver and 1500+ hours in black

Get Expert Advice

Get Expert Advice  enquiries Now

enquiries Now quality Certificate

quality Certificate Achievement

Achievement